Our Blog

So You Want To Go Racing Part 5: Parts Breakdown & Cost

This is the part many of you have been asking for, what parts did you use, and what’s a ballpark price to build a race UTV?

Starting off, we chose the RZR platform as we had more access to better deals on the parts. If I started again tomorrow, I’d seriously consider an X3 2 seat platform as well. I think these two cars have the best wheelbase options, and are the MOST ideal for a Turbo UTV race build. From participating and watching the NA class, I would choose either a 2 seat RZR or a Artic Cat Wildcat XX. I think the extra weight of a longer chassis don’t do you any favors, and the top performers in the NA class are in simple, light RZR’s. The Wildcat’s looked really strong at the UTV World Championships, but they weren’t reliable at that race. Ultimately, if I wanted to commit to desert racing, buying a used NA UTV and racing Best In the Desert would be a good choice. That class is more evenly matched, the Turbo class has a lot of big money teams and sponsorship, and you can pick up a sorted out NA race UTV for $30,000 or less.

For the parts, we chose to mention all prices at MSRP. We did get better deals on many items, and having access to deals, or being sponsored can help a lot, and really drive down the costs. With all of the parts selected, we tried to choose what we thought was a great value. For the suspension kit, in hindsight, we would have probably chosen the Cognito Motorsports kit, as its reputation is unmatched. But so far we haven’t had issues with the Lone Star kit, and hopefully none moving forward. We splurged on the Rigid Adapt light bar, as we had access to a good deal, but unfortunately, we cannot use it as it draws too many amps (you will hear more about these issues in a future video).

I’ve only owned stock vehicles, and honestly I’m amazed how well they hold up. I’ve learned a lot about the elements of this race car, and I can tell you that you need to be open minded on your budget, and “budget” and “racing” aren’t 2 words that should go together. I think there are certain parts you need, and corners that cannot be cut, otherwise you are putting yourself to show up and have an issue that will not allow you to finish. Hell, that could happen to us, time and race miles will tell. We just used the information at hand and tried to do our best, based on our budget. We’ve heard of racers having issues with parts that others view as “top of the line”.

Ultimately, that’s what this video series is about- to give you all the ins and outs, to educate and hopefully save you time and money, and give you feedback on what’s working well for us. Now it’s time to tune the suspension and motor, and get ready for a few races this fall!

Transcription:

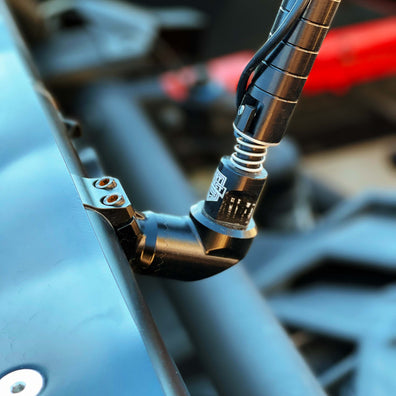

So you want to go racing part five let’s get down to the brass tacks how much it cost to build this razor so I think the easiest way to break this down is to talk about the vehicle used the cost of the parts at MSRP value and then the extra labor and fabrication involved so starting off with the vehicle I started off with the 2017 razor turbo the only thing that I still used from the stock turbo where the engine the transmission differential front driveline brakes hubs front bodywork the stock Fox 2.5 and 3.0 internal bypass shocks as well as the stock wiring harness one little tip so let’s say you get a razor for for twenty two thousand dollars a lot of these parts that you’re not going to use you can sell make a few thousand dollars back ideally maybe you can find a crashed razor with a good motor and trans and driveline that would probably be your best and most economical bet just to get what you need so moving on to the chassis the chassis was built by fab works a small fabrication company in the Los Angeles area the chassis was $12,500 so here are the photos of what it looked like when I picked it up that includes taking a stock for seat frame rail completing all the fabrication work needed for the roll cage moving the seats relocating the seats as well as the steering rack and all the body panels as well as mounting up the stock front fender hood and a side fenders the fuel cell was already installed and right here was supposed to have been installed but there was an issue so there was an upgraded radiator and we had to install that ourselves the chassis came mounted for seats but it did not come with any other mouth tabs other than for the two front lights in the front bumper I sent fab works the lights I wanted to use in the front bumper they built the bumper accordingly and fab works asked my opinions on what I wanted to chassis to look like they have made multiple iterations of this chassis and this chassis is about five inches lower than previous versions they had built just a few months sooner so I loved how it turned out I love that it has a flat top you know the radius would look good as well but they asked for my opinion on what I wanted for all of those things for suspension I went with the Lonestar long travel kit which also included their heavy duty sway bar kit and their heavy-duty rear radius rod box I started off with the Lonestar axles which were set with the stock Seavey’s I have recently updated to Rhino 2.0 super ATV axles as I broke alone start axle pretty easy and just didn’t have a good feeling about those being real race ready so the chassis took a lot longer than anticipated for them to finish it so as a gift they threw in a super ATV steering rack which was $300 value for the radiator ballast on an issue an axe that we damaged the radiator that was in the car so they upgraded me to the CBR which is specially designed for a razor with the integrated intercooler that’s thirteen hundred and seventy nine dollars and that is the model six zero seven nine for fuel cells I’ve got a fuel safe enduro 25 gallon cell this is about 15 hundred and thirty dollars as that includes a forty five-degree filler neck as well as they fuel gauge that we installed the upgraded fuel rail was about two hundred and twenty dollars that’s just peace of mind and we didn’t want to go with the stock fuel rail right away before we installed the driveline we upgraded to a sand craft carrier bearing which is about two hundred and forty dollars for the – to come up with a UTV race back and we added a few sensors for oil pressure boost pressure and the belt temp that’s about 11 hundred dollars for all those items moving on to suspension like I said I kept the stock fox 2.5 inch front I know rear internal bypass but I sent those off to shock therapy let them know is for a race car build for a long Lone Star long travel kit so for about $1,500 shock therapy respring revolve and added crossover rings to those stock shocks those shocks are matched up to a Lone Star a long travel kit which is about fifty five hundred dollars that includes the bigger radius rod rear box cage which is welded as well as their heavy-duty sway bar kit moving on to the wheels I went with Walker Evans 15 by 6 HB lock wheels those are about $1,100 and around those wheels are some ATP ultra cross r-spec 32-inch tires so about 750 bucks for five of those movie under the seats the Sparco seats are about $1,900 and we ultimately had to add the bases which requires some cutting and welding from the fabricator so now the spark OC bases allow us to simply unbolt them and move them around based on how tall or short to drive her passenger are so moving on to the lighting up top I’ve got a 40 inch rigid adapt light bar that’s about 2,400 dollars and this thing is putting out almost 30,000 raw lumens speakin of lumens I’ve gotten ninety five hundred lumens each on the front bumper with some of the rigid d2 accel lights the pair of lights and the front bumper is about four hundred and fifty dollars moving back you’ve got a full race jack I chose the fola screw jack that’s three hundred and fifty dollars for communications we’ve got a PCI 50 watt radio and intercom setup that’s about nine hundred and ninety nine dollars and for our fresh air setup using the rugged and three pumper setup which I love they’re expandable hoses that comes out to four hundred and eleven dollars on the bottom of the frame I’ve got a Polaris hmw skid plate which is seven hundred and seventy nine dollars the grant steering wheel with the quick-release is two hundred and twenty five dollars for GPS I had an old iPad laying around it’s a genuine eye when I use the X GPS sensor all together I’ve got about 250 bucks into that long with the RAM melt where it screws right on to the dash the chassis was recently coated and steel it that’s about two hundred and fifty dollars we use just over a case I recommend if you’re going to do that to erase chassis buy a case and a half just to have a little bit extra like I mentioned earlier I did upgrade recently to some Rhino 2.0 axles from super ATV those are about 13 hundred dollars which includes a full size spare which is mounted in the rear of the racecar now the motor is essentially stock but we did upgrade the ECU mapping and clutch tuning with a local tuner that was about 16 hundred dollars now those are all the high points of all the parts that I used but about twenty three hundred dollars went to miscellaneous items for fabrication fittings other brackets things that were needed to put everything in place that chassis comes pretty bearish they’ve kind of got a welled up what you need where you need it and go from there this also includes some of the cost this also includes the parts for the custom air intake as well as the custom removable storage rack that Brent had American engineering built in the final finishing pieces we got all the body panels powder-coated which was about two hundred and seventy-five dollars and then the whole car was wrapped which was about 18 hundred arms because it’s got a little bit of higher-end reflective wrap on the company logo on the side of the car so labor you can obviously save a ton of money if you’re capable to do all of this yourself to fab to wire there’s a lot of skills that’s involved in putting this thing together and getting it dialed if you were lucky enough to get some money to build this for around 40 bucks an hour so Brett Mann an American engineering has been skilled and off road fabrication for over thirty years it took about a hundred and fifty hours of his time to do all the mounting teardown and final prep fabrication wiring and obviously we had a couple things going to go back and double-check as the car was running for instance where we located the radiator was in a great spot but then that coached on the filler for the fuel cell which necessitated the need of a 45-degree angle filler hose so a couple pieces that Brent had already fed there we had to go back and change these type of things you don’t really figure out until you get the whole card together so all said and done and the sarpy on all of these parts is just over thirty nine thousand dollars I was able to get certain deals on some of these items bringing my cost down thankfully that does not include the initial cost of the raiser nor does that include the fabrication work which like I said if you do a rough estimate forty bucks an hour if you’re lucky 150 hours that’s an additional $6,000 in labor so things add up quick and where we’re at right now is in my opinion a car that is Ray scible there are going to be some things where we need to think about upgrading in the future like an alternator so I can run a night race and make sure I’ve got plenty of power to run lights for hours on end if we did a race like Vegas or Reno or the Baja 500 probably going to spend some more money in the future with clutch tuning maybe working more on a custom clutch cover off of a turbo s or better air ducting if we can’t keep our belt temps low that remains to be seen so far been pretty good but we haven’t really pushed it in a race situation so hope this gives you some ideas if you’re thinking about going down the rabbit hole of building a race car yourself honestly if I was to do it over and I just wanted to go racing I’d probably find a used race car you’re gonna get a good deal on it you’re gonna get somebody who’s that a car that they’ve already learned the ins and outs and sorted out a lot of the bugs if you watch our last video we had a lot of bugs that needed sorting out some of these weren’t that make a big deal some of them ended up being fairly expensive these type of things led us to go over my budget the tuner and of costing me a lot more than I anticipated the axles I initially thought would be okay we’re not so these are just the type of elements everyone talks about when you do something you’re gonna go away over your budget I went over mine but it’s off-road racing so you’re gonna have a budget you’re gonna go over it be generous with that budge you’re gonna learn a lot I’ve learned a lot about this vehicle I’ve learned a lot about how a razor comes together some of the challenges when you do go from just a regular store bill vehicle honestly after building this race car the charm of the stock side-by-sides is even higher for me the fact of how reliable all the stock side-by-sides I won’t have been you can get your warranty how much of a beating they really take I think is really really impressive so now that I’ve seen that I see on a whole other level building a race car and having just a lot of little issues that have caused me to be stranded caused you know more money to come out of pocket so I think this is one reason why these side-by-sides have slowly been killing the same car market they’ve been killing the prerunner market because when you’ve gone down the rabbit holes like myself with a race car or a sand car or a prerunner these type of things happen you’re going to have issues and there’s a there’s a charm to just being able to go jump in these side-by-sides film with gas take care of them do your prep and you’re gonna be happy and of a lot of trouble-free miles so yeah you’re gonna spend more than you probably thought you’re gonna have some trials and tribulations but honestly this has been a lifelong dream for me I can’t believe that I owned this car I’m so excited to to go racing as a youngster I’ve always wanted to go desert racing I love the idea of a driver and a co ride or a team working together we might might be at the Norra race in 2020 I think that would be the amazing opportunity to get together with some friends and family and have a full experience all the way down the Bob and insula without it being a non-stop race so I’m really excited I’m really excited to just tune the car you need to see a lot of videos coming up where we’re tuning the suspension playing with the lighting all the other nuances of the car and then it’s gonna be race time so dream come true couldn’t be more excited to really really push this thing and now it’s time to prepare so it was time for me to line up in a starting line and and see how it goes and learn about how to become a better driver where I’m not beating up the car but I’m getting a getting some good results so let’s give the exciting process I’ve playing in the dirt my whole life but this is a whole new challenge and stay tuned to our channel if you want to see how this Cardo is that its first race coming up here pretty soon you.

LEAVE A COMMENT